I have fond memories of the Operations Management course I took in college. We spent an entire hour playing the “Beer Game,” which had nothing to do with drinking beer. Through this game, we learned how “just-in-time” production works: how to work collaboratively to keep inventory levels low and still meet demand. Little did I know that Electronic Data Interchange (EDI) is an essential part of the communication between supplier, distributors, and retailers in the real world “Beer Game.”

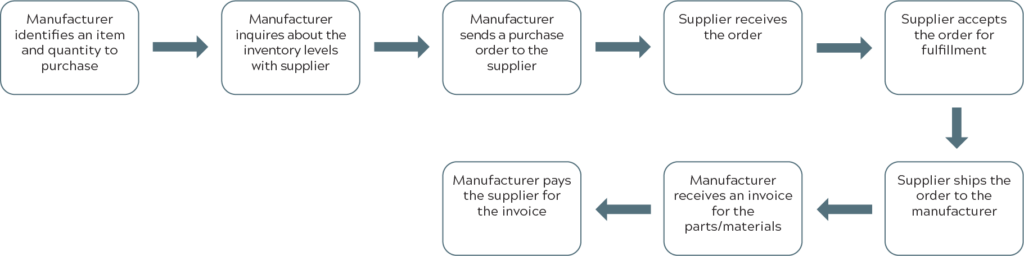

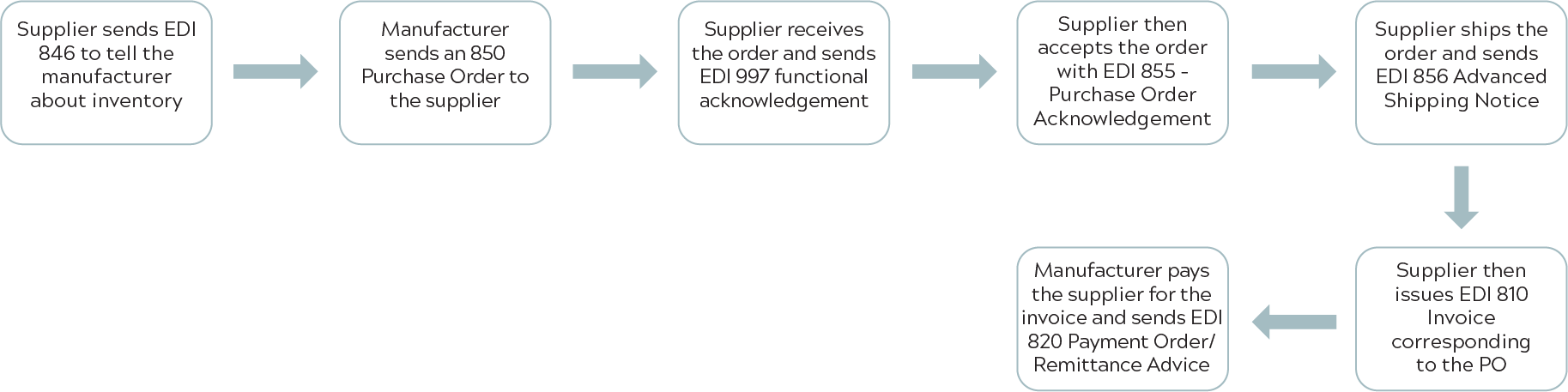

The Procure to Pay flow

A typical “Procure to Pay” use case for a manufacturer looks like the cycle below.

Without an EDI system, a manufacturer will have to assign people resources to manage partner communications. Every time a communication (order, invoice) is received from a business partner, someone from the manufacturer has to manually enter the same information in their Enterprise Resource Planning/Supply chain management system, and then respond back to the supplier with an appropriate response.

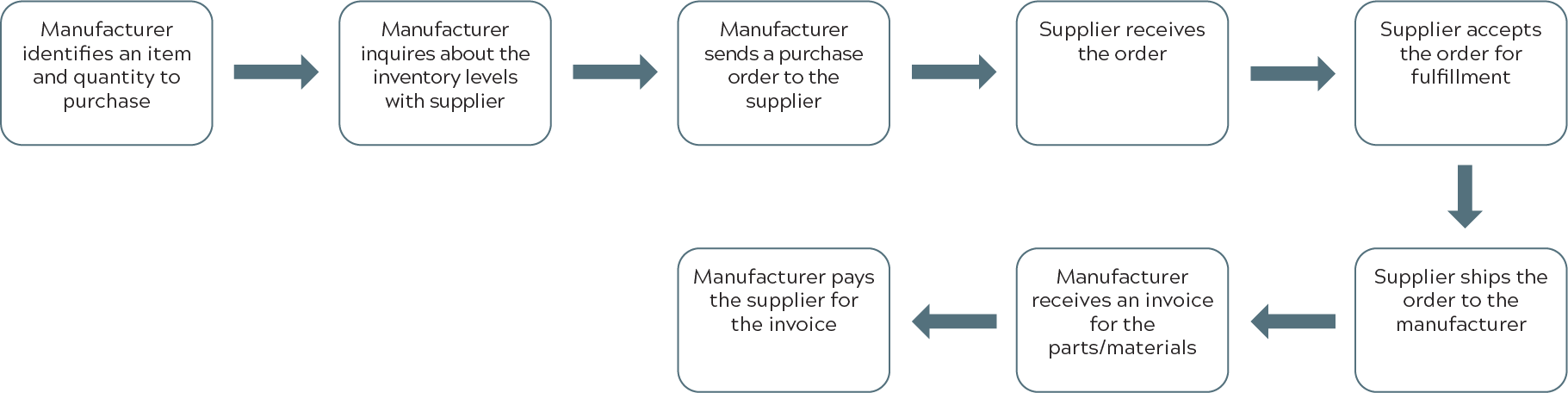

With EDI, you can increase the efficiency by automating transactions such as responding with an acknowledgement once an order or invoice is received. By automating transactions, you can eliminate manual data entry errors and associated costs. EDI also enables you to process business documents faster and reduce the overall cost of doing business. An EDI solution typically consists of an EDI gateway that communicates externally with your trading partners with pre-determined formats, messages, and protocols. Common EDI formats are X12, EDIFACT, HL7, Tradacoms, SWIFT, etc. The two most common formats – X12 and EDIFACT – are prevalent in both the US and Europe.

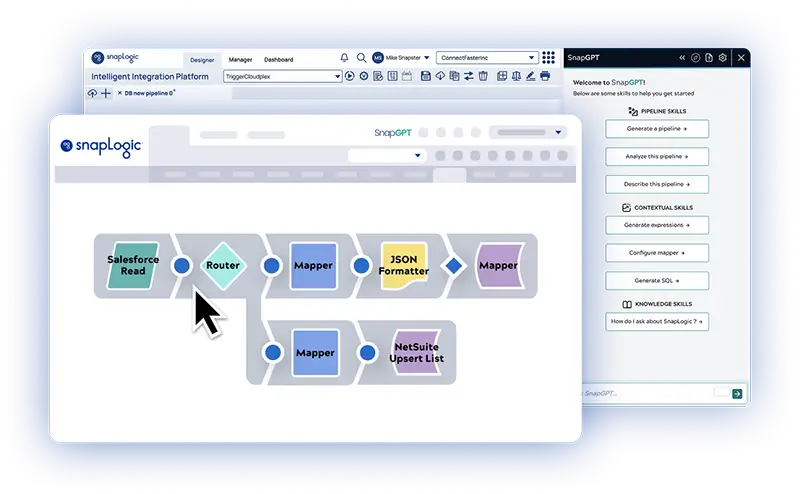

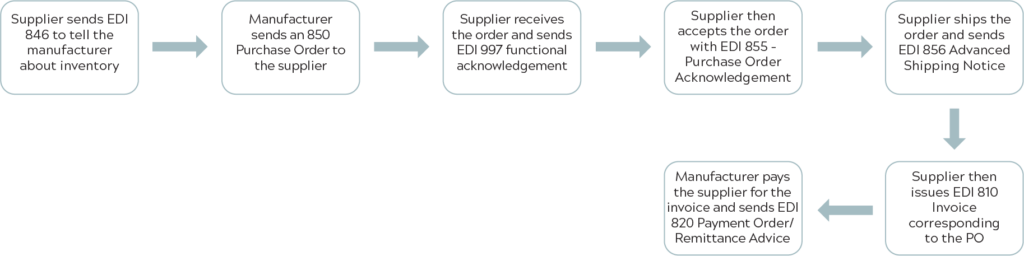

The Purchase Order to Invoice Cycle – with EDI

Now let’s see how the above Purchase Order to Invoice cycle looks with EDI.

Six advantages of adopting EDI in manufacturing:

Six advantages of adopting EDI in manufacturing:

- Automate processes and notifications thus reducing man-hours and eliminating error-prone manual actions

- Enable real-time data integrations with key systems of records such as Enterprise Resource Planning (ERP) or Supply Chain Management (SCM)

- Realize operational efficiencies by

- reducing hours of routine tasks such as preparing shipping documents, sending advanced shipping notices, etc.

- making it easy to locate materials throughout the production process

- Empower organizations that use lean manufacturing tools and processes such as just-in-time by giving them better control over inventory

- Reduce TCO with automation, error reduction, operational efficiencies, etc.

- Increase revenue as EDI allows an organization to work with large customers who often have EDI as the base requirement for doing business

In today’s fast-paced real-world “Beer Games,” manufacturers need to be agile to quickly respond to changing customer needs. Moving beyond legacy systems and processes and adopting a modern B2B integration/EDI solution is key to gaining that agility and keeping up with partner demands.

Learn how EDI enables global business and eliminates technology debt in the ebook, “Intelligent B2B integration: How modern EDI can leapfrog into the cloud.”